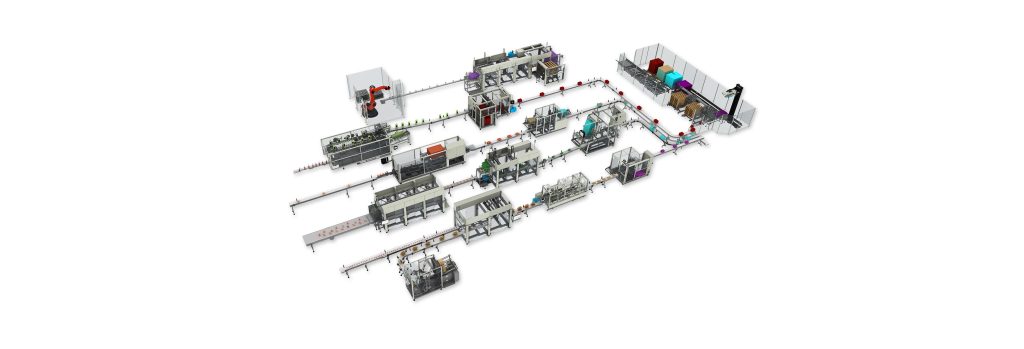

With over 45 years of history, Imball develops and supplies worldwide secondary packaging machines & turn key systems. Experience, know-how, reliability together with worldwide support and service, allow us to act not just as a supplier but also as a partner, proposing and developing innovative packaging solutions.

Non-stop research and innovation and the regular and constructive dialogue with our customers allow us to offer machines and systems constantly updated for:

- easy & quick formats changeover

- latest technological evolution

- safety and ergonomics requirements

- reduction of maintenance

“QUALITY” has always been a keyword to us, and our best reward is the trust of our many satisfied customers, who appreciate the superior construction technology of our machines, which are able to withstand the most hostile of operating situations, as well our quick and constant support and service.

MAIN APPLICATIONS:

Tray/Carton formers & closers which ensure maximum flexibility & high efficiency for all applications, starting from “Flat-Blanks” with glue or lock type forming.

Side & Top loading case packers for RSC, equipped with standard or customized collating systems, designed to perfectly fit customers’ products shape, speed and configuration into the cases.

Imball Delta Robots of internal production with special tools allow us to vaunt a Side/Top loading system in one single machine, the case packer AV-R, with automatic size change over.

Wrap Around systems with traditional side loading or robotics if fast automatic size change over is needed. Shelf-ready Displays obtained from lids applicator or integrated solutions for displays made of 2 pieces (Tray & Hood).

Multipack Sleevers to wrap within carton sleeves one or more products as cans, jars, bricks or bottles and then glue the bottom by hot melt.

Imball offers several models which differ in speed and construction, but all of them so flexible as to manage different products and pack configurations as single line, double line or double floor with top speed of 70 up to 300 packs/min, according to the chosen model.

Bottlepack which are vertical cartoner to load luxury wine and spirits bottles of different shape and dimensions into gift boxes, available for glued or lock-type bottom closure.

Main machine’s advantages are:

- High performance for speed and reliability

- Easy & quick size change-over with possibility to upgrade to fully automatics size change-over

- High flexibility which allows a wide variety of carton/tray styles and shapes workability

- High flexibility for cardboard grade:

solid, micro and corrugated boards. - Large easy-to-load magazine.