Zar Group looks globally to see what leading blue-chip brands are using for end-of-line packaging, and Cama Group’s name comes up again and again.

The Zar Group is one of the Middle East’s biggest diversified food companies. Serving the region for over 30 years, it not only owns and operates the region’s largest pasta production site, but recent investment following a portfolio enlargement has led to the design and build of the region’s largest confectionary plant too.

With a mission to make inexpensive food available to everyone in society, by offering it quickly and at a reasonable price, the company undertook significant research and development in regard to its new factory’s operations and the technology it would deploy. A large portion of this research involved ascertaining what other leading global food brands were using, and then creating a production facility in Iran that was on a level with the best in the world – in terms of product quality, operational throughput and packaging excellence.

And with the best in the world in mind, the end-of-line packaging operations naturally included fully integrated solutions from global leader Cama Group.

“Zar Group made the decision to enter the confectionery market in 2016,” explains Afshin Mokaram, Sales Engineer Manager, at Cama Group. “This portfolio expansion was a natural progression, as the company already handled and processed many of the raw materials.”

Construction of the new plant for the newly formed Zarkam brand began in 2018 and Cama delivered its first machine in 2019, but work was subsequently stalled and put on hold for 18 months, due to the Covid pandemic. However, it started back up again in 2021 and step by step all the production lines of this company are getting ready and they are launching their products in the market..

“Interestingly, unlike many other plants around the world that specialise in single product types, this plant produces a huge variety of confectionery from a single site, including cakes, wafers, sandwich biscuits and crackers. This product variety means that the plant has to deploy a wide range of technology solutions for every element of the individual processing and packaging steps. But Cama is the only company handling secondary packaging across all the lines, no other machine supplier has this depth of technology in the plant.

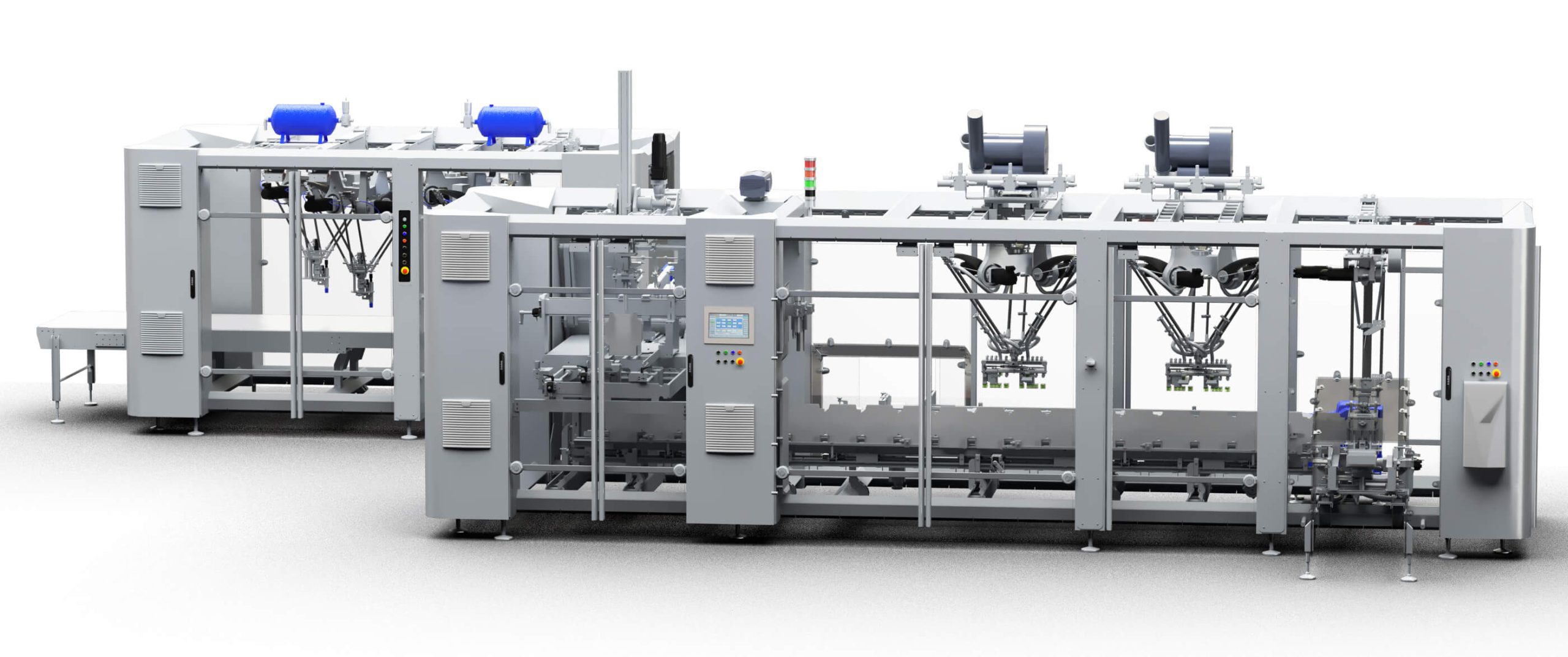

“We will eventually have a total of 24 machines in operation across six lines. One line is for mini cakes, two are for wafers, two are for sandwich biscuits and the final line is for crackers. And all the machines we are supplying are from our Breakthrough Generation (BTG).”

Cama’s BTG Series has design and operational features that are setting the standard in secondary packaging. Their modular, scalable and hygienically designed frameworks house contemporary automation solutions – including advanced rotary and linear servo technology – which can be tightly coupled to in-house developed robotics, to deliver the all important flexibility and adaptability required by modern packaging operations. The machine range is also based on a digital platform that supports full Industry 4.0 capabilities, including AR, VR and virtual testing, training and operation.

“Most of the monoblack forming, loading and closing machines we are supplying Zarkam deploy tightly integrated robotic and vision systems for pick-and-place operations – for both nude and flow-packed products, depending on the product line. There are also case packers to place the cartons into boxes. Although Zarkam is not currently leveraging the full digital capabilities of our solutions, the platform is there for them to use in future enhancements.

“For such a prestigious project, we deployed a dedicated Iranian support team for the Zar Group for installation and commissioning. Zar Group can call up on three full-time local Cama engineers, without worrying about language barriers, visas and travel times, something for which they are very appreciative.

We also acted as a consultant in the early stages, as they did not have deep knowledge of the confectionery industry. We helped them with packaging design, material selection, machine locations and product launches, based on our in-depth knowledge from other industries and applications around the world. We always explain to our customers that we are not just a supplier, we are a partner that is happy to share skills and knowledge to ensure success.

“Since the commencement of this project,” Mokaram concludes, “we have been approached by other companies within the region. Much like the Zar Group emulating its European counterparts in terms of machines and technologies, other companies in the region now want to learn from the Zar Group and deploy best-in-class technology. And with our foothold and support team in place, we are ideally placed to serve these customers too.”

A spokesperson at Zarkham explains: “To be the best in the world, you have to use the best in the world, so it was essential that we chose technology partners that could help us achieve our aims. Cama’s machines are used by many of the world’s leading confectionery brands, so we know there is an established pedigree behind the name. Their digital infrastructure makes integration easier, and the user interface is the same across all the Cama machines, so there is less to learn for the operators. The support before, during and after installation and commissioning has been excellent.”

Mr. Mohsen Amini CEO at Zarkam