The vocation of BBM Service is to give quality services for bottling and packaging, pursuing the recovering philosophy which has been part of our company since its foundation. From simple maintenance of machines to the engineering of a line, the answer to the production and budget demands of the customer moves towards the lowest possible impact on the environment and the sharing of the best practices with the personnel of the production site.

This ability to combine recovering and efficiency makes BBM Service an appreciated partner for many customers.

That has led to our steady collaboration with large companies for the supply of maintenance and upgrade services on machines and lines. Over the last few months, we have worked for one of the major water bottling companies of Italy indeed, for a project which has shown even better our capacity to add value to the available resources, always aiming at regeneration and sustainable production.

The project, for the upgrading and the increasing of productivity of the site, has involved BBM from the designing of the new layout of the line, with the implementation of refurbished supplied machines, refurbished machines from other sites and new machines.

Having a closer look at the specific activities we have done, it comes natural for us to start from the supply of refurbished machines which is among our strengths. For this customer, the machines we have supplied are a blow moulder and a shrink-wrapper completely overhauled , upgraded and ready for the production site, with the goal also of using less plastic.

Thanks to our support, the client has been able to allocate some machines from other production sites of the group, some closed and some needing a machine upgrade, to the plant of this project and for which they represent an improvement in terms of capacity.

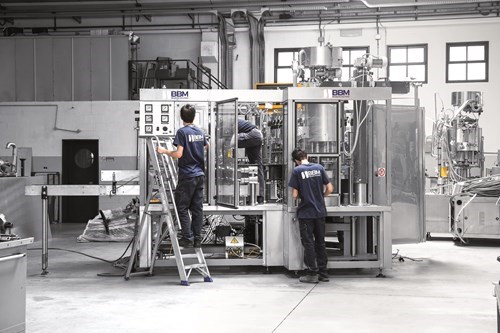

The machines we have relocated for this line are the filling machine, the palletizer and the labeller, next to several sections of conveyors.

Obviously, relocation means also disassembling and assembling, but also being in charge of transportation. Furthermore, refurbishing, changes of format and conversion have been necessary to get the machines ready to work in the new line with also lighter performs. All these activities have been carried out by BBM Service directly in the working site.

The relocation done in accordance with the customer represents an interesting opportunity for every producer with more than one bottling and packaging factory, who can exploit the upgrade with new machines and the end of activity in some lines to give new value to another one, thanks to our work.

As already said, the project involved also the use of brand new machines which we set into the new layout of the line and for which we have taken care of the orders and the supply. The new machines are the stretchwrapper, the handle applicator and the bottle inspection device.

To conclude the installation activity of the line, we run the testing to deliver to the customer a turnkey system. The numbers of the project are what stands out though, the line has doubled its hourly production (from 8.000 to 16.000 bph), reducing the weight of the plastic performs (4 g less per each perform) for a total saving of around 250.000,00 Eur per year, which by itself means the return of the 1.000.000,00 Eur investment in few years.

An increased productivity can be translated also in potentiality to better meet the demand of the market, and consequently an improvement in the organization of shifts. Only to mention the immediate benefits.

Here it is the perfect example of how BBM Service may be the unique reference point of the customer for the many activities needed on a line, from servicing, to purchase, going through installation, with a well established structure, with two facilities, more than 30 permanent technicians and well defined departments to serve the customer in the best way. This is the plus offered by BBM Service, which is now recognised and sought-after in the sector of bottling and packaging..